The lightweight belting market is primarily made up of thermoplastic covered, solid plastic, lightweight rubber, and non woven belting. Each of these categories offers unique properties and advantages as summarized below.

Light Weight Conveyor Belt

The lightweight belting market is primarily made up of thermoplastic covered, solid plastic, lightweight rubber, and non woven belting. Each of these categories offers unique properties and advantages as summarized below.

Product Details

Technical Parameters

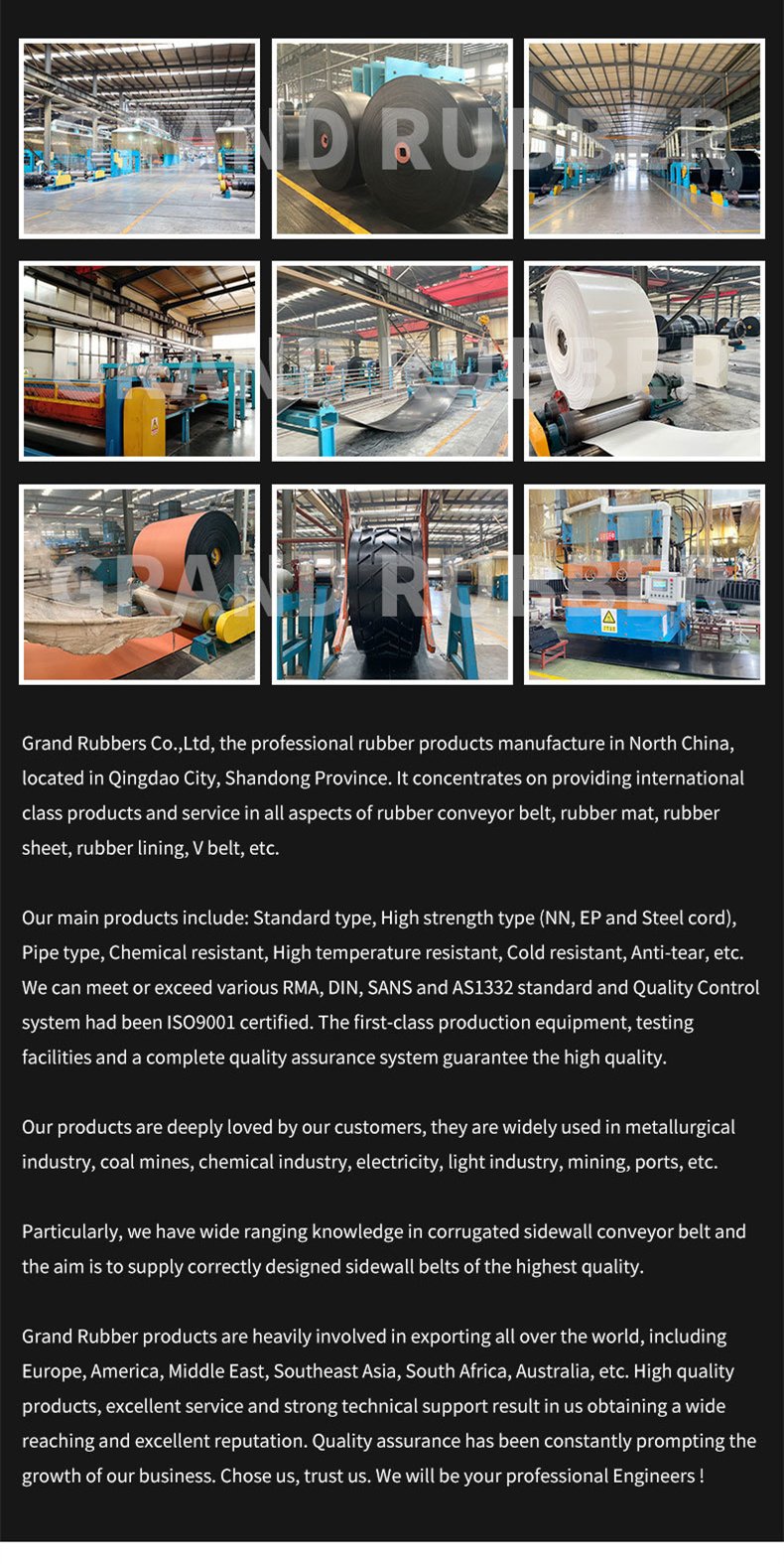

Company Overview

What is lightweight conveyor belt

The lightweight belting market is primarily made up of thermoplastic covered, solid plastic, lightweight rubber, and non woven belting. Each of these categories offers unique properties and advantages as summarized below.

Product Features

Thermoplastic coatings that can be melted and rehardened while retaining the material physical properties characterize this segment of belting. This property provides the unique advantage of high quality heat welded splices and the ability to configure belts for specific applications by adding a variety of belt accessories. The most common covers are PVC, polyurethane, and polyolefin. These cover materials provide a wide range of properties such as cut/abrasion resistance, chemical resistance, oil/fat resistance, product release, high/low friction, impact resistance, and sanitation.

Product Use

1. Food Processing: Industries such as bakery, confectionery, snack foods, meat and poultry, dairy, fruits and vegetables, and seafood are some examples of where lightweight belting is utilized. Automation of the manufacturing processes has led to small pulleys and process conditions that lend themselves to the flexibility and versatility of lightweight belting. The thermoplastic, heat-welded splices provide superior reliability, flexibility, and sanitary properties.

2. Unit Package Handling: Conveyors in post office, distribution centers and airports are becoming lighter and faster, while requirements for noise are becoming more stringent. This favors the longitudinally flexible, low friction/ low-noise polyester fabrics used in certain lightweight belt constructions.

3. Other Industries: Other major industries that utilize lightweight belting are pharmaceutical, treadmill, electronics, plastics, bottling/canning, textile, wood/paper, and tobacco.

Executive Standard

China GB/T7984 Standard

Germany DIN22102 Standard

US RMA Standard

UK EN ISO15236 Standard

Japan JISK6322 Standard

Australia AS1332 Standard

Main Technical Parameters

thickness | 1.0 | 2.0 | 3.0 | 4.0 | 5.0 | 6.0 | 7.0 | 8.0 |

Product mix | One cloth one glue | Two cloth two glue | Two cloth two glue | three cloth three glue | three cloth three glue | Four cloth four glue | Four cloth four glue | Four cloth five glue |

Operating temperature | -15°/80° | -15°/80° | -15°/80° | -15°/80° | -15°/80° | -15°/80° | -15°/80° | -15°/80° |

Weight(kg/m2) | 1.3 | 2.7 | 3.9 | 5.02 | 6.2 | 6.3 | 7.8 | 8.8 |

Elongation required tension | ≥8 | ≥8 | ≥8 | ≥12 | ≥12 | ≥20 | ≥30 | ≥35 |

Minimum roller diameter

| 20 | 30 | 60 | 80 | 80 | 180 | 180 | 320 |

FAQ

Q1. How about your experience?

We have mainly produced rubber conveyor belts for over 20 years.

Q2. What are your main products?

Multi-ply fabric conveyor belt(EP/NN type), steel cord conveyor belt, chevron conveyor belt, sidewall belt, white conveyor belt, bucket elevator belt, filter belt, and special conveyor belts with the characteristics of heat resistant, cold resistant, oil resistant, flame retardant, abrasion resistant, etc.

Q3. What about the lead time?

1) 3--5 days for sample.

2) 20--25 days for mass production. If urgent, we have the green channel.

Q4. Can you send free samples?

Yes, we provide samples for free after inquiry.

Q5. How about the package?

Standard export packing method, your special requirement will be respected.

Q6. What are your Payment terms?

T/T or L/C.

Q7. Can you do door-to-door?

No problem.

Q8. How do you ensure your product quality?

Our quality control system had been ISO9001 certified. The first-class production equipment, testing facilities, and a complete quality assurance system guarantee high quality.

Q9. What is your major market?

Our products are heavily involved in exporting all over the world, including Europe, America, the Middle East, Southeast Asia, South Africa, Australia, etc.

Q10. What you can do to support me better?

We can provide products that meet quality standards, timely delivery, transportation packaging requirements, and customers' other special requirements.

Reviews

We’ve worked with GRAND RUBBER on several orders of corrugated sidewall conveyor belts, and they’ve never disappointed. The belts are strong, precisely made, and perform perfectly in our heavy-duty applications. Their team is responsive, knowledgeable, and always delivers on time. A reliable partner we trust.

GRAND RUBBER has been our trusted supplier for mining conveyor belts for many years. The belts are tough, reliable, and perform exceptionally in demanding environments. Their consistent quality and fast delivery make them a key partner in our operations.

We are very satisfied with GRAND RUBBER’s conveyor belts. They are highly durable, cost-effective, and perfectly suited for our mining operations. Delivery has always been on time, and the quality remains consistent with every order. A dependable supplier we can count on.

Write a review

Inquiry Now