Product Classification

Chevron belting is composed of the belt carcass and pattern, since the material to be conveyed and the angle of inclination of the conveyor is different, the shape and height (depth) of the pattern is different. The angle includes a 0~45° inclination angle. And the pattern type includes V type, Cylinder type, U type, etc.

Product Structure

Chevron Belting is made up of several layers of materials, including a carcass made of synthetic fabric or steel cords embedded in rubber, a top cover made of high-quality rubber with a chevron pattern, and a bottom cover made of rubber that protects the carcass from damage.

Product Features

1. The bonding strength between the pattern and the belt body is high.

2. Large conveying angle, not easy to slip.

3. Excellent physical properties of rubber, high adhesion, and fatigue resistance.

4. Better cleat rubber property and abrasion extend the service life of the conveyor belt.

Product Use

Chevron belting is commonly used in the transportation of bulk materials in industries such as mining, quarrying, construction, and agriculture. The unique design provides excellent grip and prevents materials from slipping or sliding during transportation.

Executive Standard

Chevron belting is manufactured in accordance with various industry standards such as ISO 14890, DIN 22102, AS 1332, and BS 490.

Main Technical Parameters

Technical Parameter | Description |

Belt width | 400mm - 3200mm |

Chevron height | 5mm - 32mm |

Chevron spacing | 125mm - 1500mm |

Belt thickness | 4mm - 30mm |

Top cover thickness | 2mm - 10mm |

Bottom cover thickness | 1.5mm - 10mm |

Ply | 2 - 10 |

Tensile strength | 250N/mm - 3500N/mm |

Temperature range | -25°C to +200°C |

Filler material | Cotton or EP Fabric or others |

Elongation at break | 10% - 25% |

FAQ

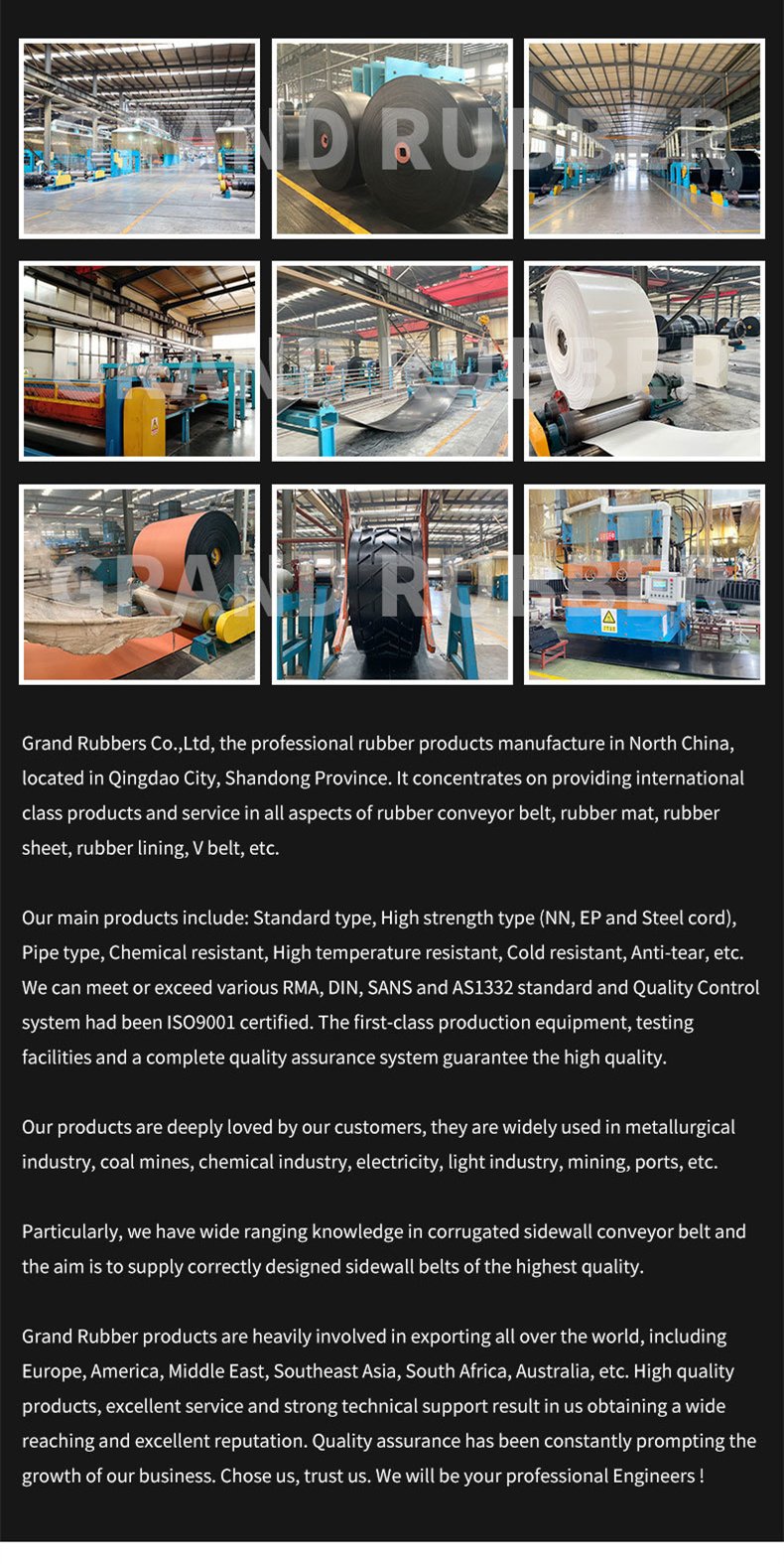

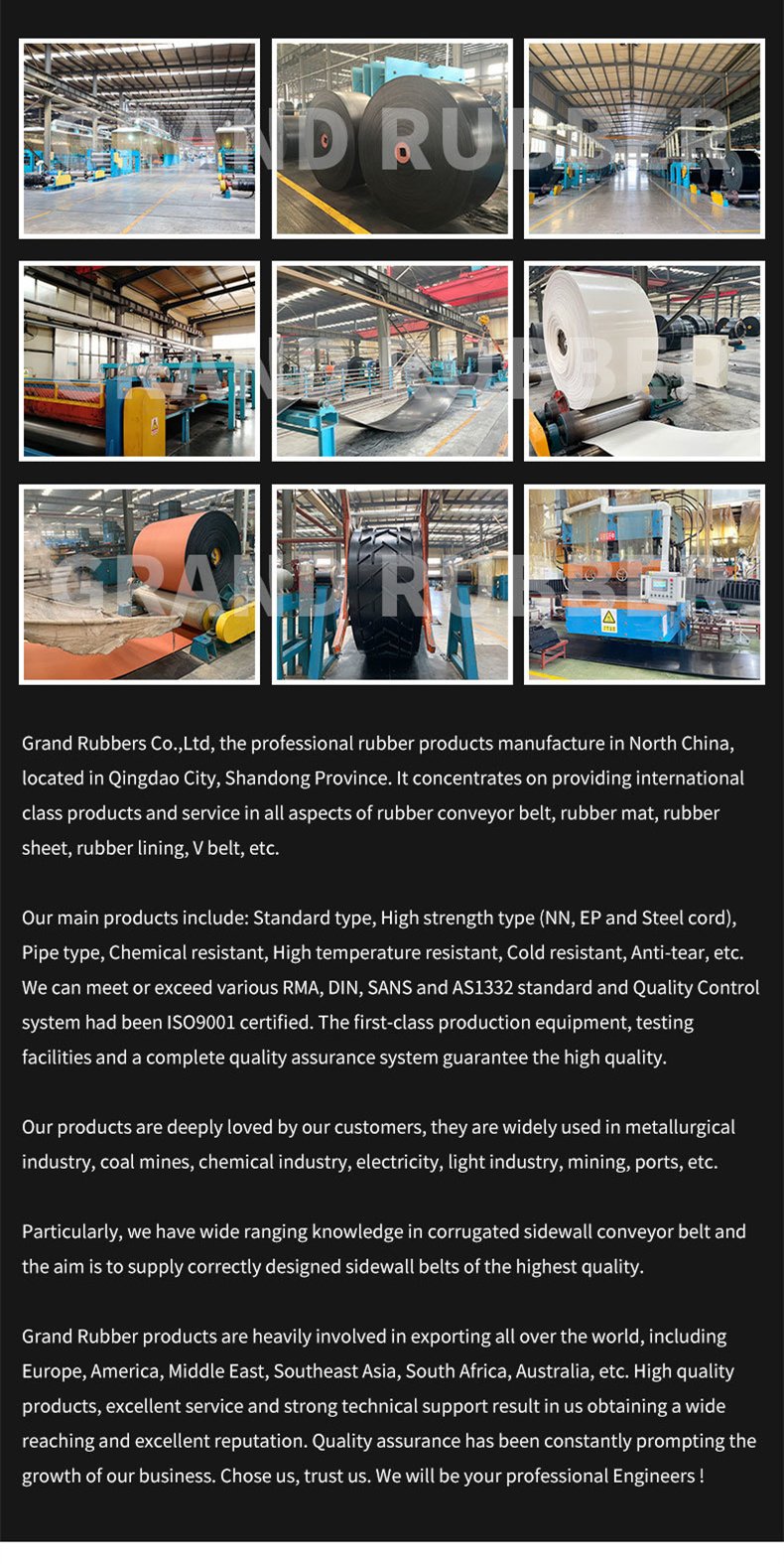

Q1. How about your experience?

We have mainly produced rubber conveyor belts for over 20 years.

Q2. What are your main products?

Multi-ply fabric conveyor belt(EP/NN type), steel cord conveyor belt, chevron conveyor belt, sidewall belt, white conveyor belt, bucket elevator belt, filter belt, and special conveyor belts with the characteristics of heat resistant, cold resistant, oil resistant, flame retardant, abrasion resistant, etc.

Q3. What about the lead time?

1) 3--5 days for sample.

2) 20--25 days for mass production. If urgent, we have the green channel.

Q4. Can you send free samples?

Yes, we provide samples for free after inquiry.

Q5. How about the package?

Standard export packing method, your special requirement will be respected.

Q6. What are your Payment terms?

T/T or L/C.

Q7. Can you do door-to-door?

No problem.

Q8. How do you ensure your product quality?

Our quality control system had been ISO9001 certified. The first-class production equipment, testing facilities, and a complete quality assurance system guarantee high quality.

Q9. What is your major market?

Our products are heavily involved in exporting all over the world, including Europe, America, the Middle East, Southeast Asia, South Africa, Australia, etc.

Q10. What you can do to support me better?

We can provide products that meet quality standards, timely delivery, transportation packaging requirements, and customers' other special requirements.